Dedicated to a higher standard.

With over 100 years of expertise, Lovink delivers proven, high-performance solutions for medium voltage underground splices. We focus exclusively on providing reliable and durable connections, ensuring performance, safety, and long-term value.

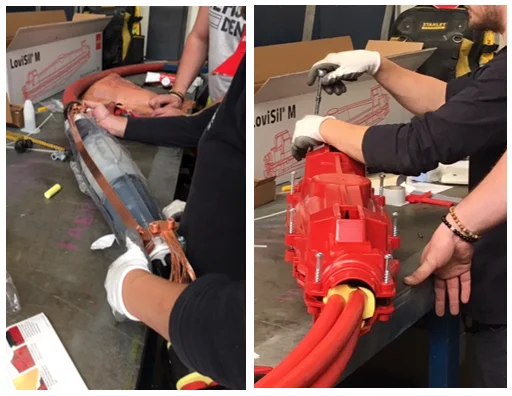

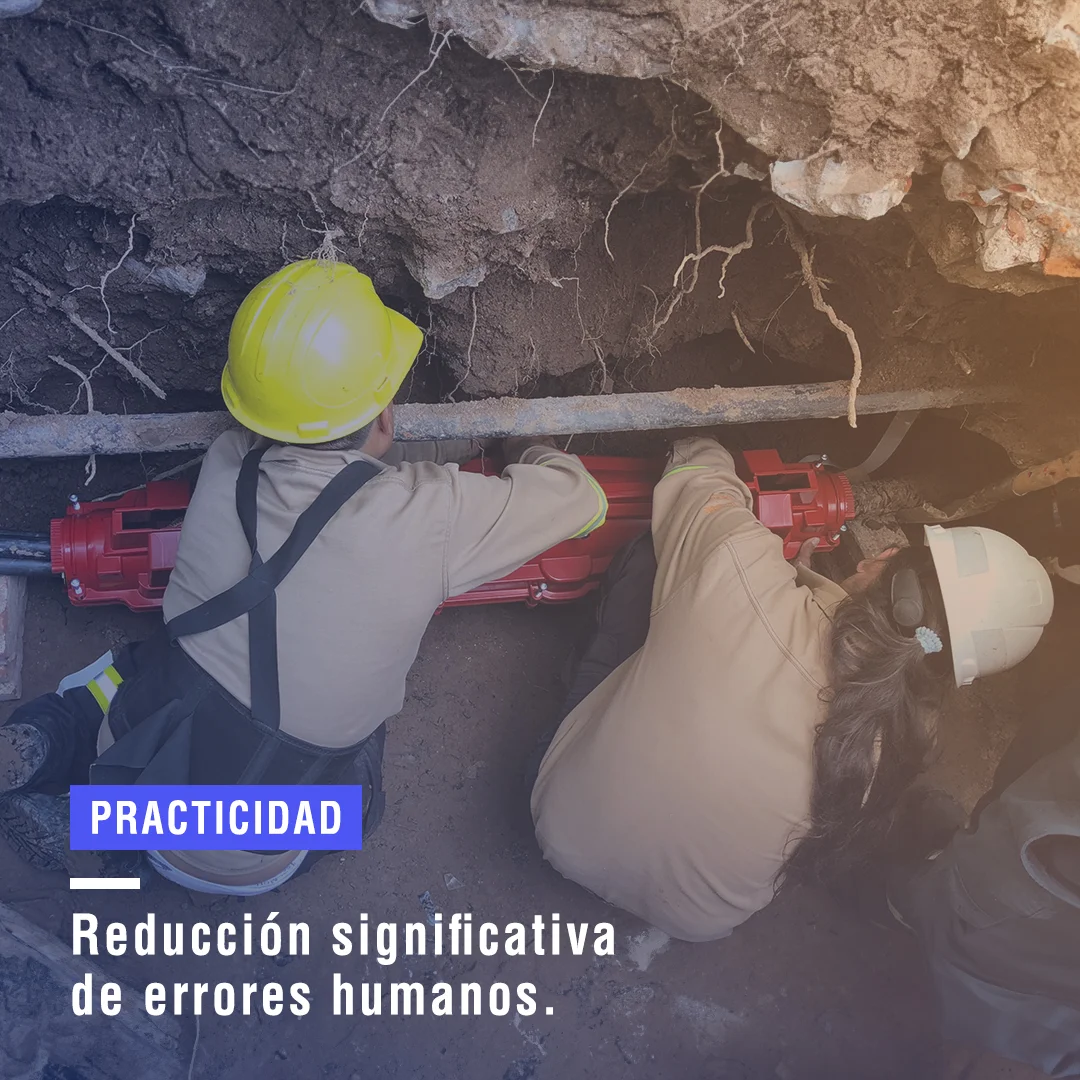

Engineered for the future, our products are crafted to last, preventing moisture ingress and withstanding fluctuating loads and high temperatures. Designed with ease of installation and safety in mind, we minimize downtime and maximize efficiency.

At Lovink performance isn’t just a promise, it’s our foundation

Our solutions don’t just work. They work reliably, with precision and with purpose, because we know the power we provide fuels progress across the globe. Every one of our products is engineered to stand the test of time. Because we don’t just provide power. We provide peace of mind

Discover what we can do for you:

Dedicated to a higher standard

Superior

Protection

Lovink products deliver reliable, highly protected connections ensuring grid stability.

Rapid Delivery of Lovink Cable Splices to Aruba

Earlier this week, several neighborhoods in Aruba were hit by a major power outage. Recently, Aruba has been increasingly hit by disruptions in the power grid, prompting network operator ELMAR to seek a swift and effective solution.

Lovink splices for Pulrose bridge reconstruction

Buenos Aires opts for certainty LoviSil® technology

Lovink straight splices in large mine project South Africa